Nondestructive testing equipment is an indispensable and effective tool for industrial development. To a certain extent, it reflects the level of industrial development of a country, and its importance has been recognized. So, what features does the nondestructive testing equipment have?

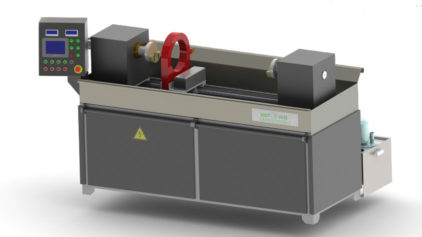

Fig.1 Magnetic particle testing equipment

1. It does not damage the material and structure of the test piece

The biggest feature of nondestructive testing equipment is that it can be tested without damaging the material and structure of the test piece. Therefore, after nondestructive testing, the inspection rate of the product can reach 100%. However, not all projects and indicators that need to be tested can be non-destructively tested, and nondestructive testing techniques have their own limitations. Some tests can only use destructive tests, so the current nondestructive testing is not a substitute for destructive testing. That is to say, the evaluation of a workpiece, material, and equipment must compare and match the results of the nondestructive testing with the results of the destructive test to make an accurate assessment.

2. Need to choose the right time to implement non-destructive testing

When preparing for nondestructive testing, the timing of nondestructive testing must be properly selected based on the purpose of non-destructive testing.

Fig.2 Fluorescent magnetic particle testing equipment (for spring)

3. Choose the most appropriate nondestructive testing method

Since various inspection methods have certain characteristics, in order to improve the reliability of the inspection results, appropriate non-destructive testing methods should be selected according to the material, manufacturing methods, working media, conditions of use, and failure modes, the types, shapes, locations, and orientations of defects that are expected to occur, etc.

4. Comprehensive application of various nondestructive testing methods

Any nondestructive testing method is not omnipotent, each method has its own advantages and disadvantages. As many methods as possible should be used to complement each other to ensure the safe operation of pressure-bearing equipment. In addition, in the application of non-destructive testing, it should be fully recognized that the purpose of testing is not to “high quality” that is unilaterally pursued with high requirements, but to emphasize economics while fully guaranteeing safety and appropriate risk ratio. Only in this way, the application of nontestructive testing in pressure equipment can achieve the intended purpose.

Fig.3 Fluorescent magnetic particle mass production type nondestructive testing line

Fig.4 Overhead uv led lamp used in the nondestructive testing line

Check out the non-destructive testing methods and introduction here.

As an innovative company with strong engineer culture, SCOUT UVLEDTM is one of the leading manufacturers for Non-Destructive Testing products and devices based in China. With over 20 years’ NDT experience, we are committed to bringing the best quality NDT UV LED Lamps and accessories at affordable price.

SCOUT UVLEDTM has a strong R&D team for technical support and extending new products year by year, we own the independent intellectual property rights and honorably have the national patents for new NDT devices. All our products are in compliance with a wide range of industrial standards such as ASTM E3022-18 and Rolls-Royce RRES 90061.

In the past years we work with our overseas clients, we understand how important the quality is, good quality helps the small business grow bigger, it is just the matter of time. We can always have a happy customer or you will always have a happy customer. Nowadays, our NDT UV LED Lamps have been sold well in China, Southeast Asia, Japan, Italy, Russia, Taiwan, Hong Kong and other countries and regions. SCOUT UVLEDTM is still looking for the capable distributors all over the world.